Understanding Stress and Strain in Architectural Engineering

Stress and strain are key to designing buildings that stand strong. In architectural engineering, these ideas help us figure out how structures handle forces like weight and wind. This article explains stress and strain, how we calculate them, and why they matter in real projects.

What Stress and Strain Mean

Think of a rubber band. Pull it, and it stretches. The pull is stress, and the stretch is strain. In buildings, we use these concepts to see how materials like steel or concrete react to forces. It’s all about keeping things safe and sturdy.

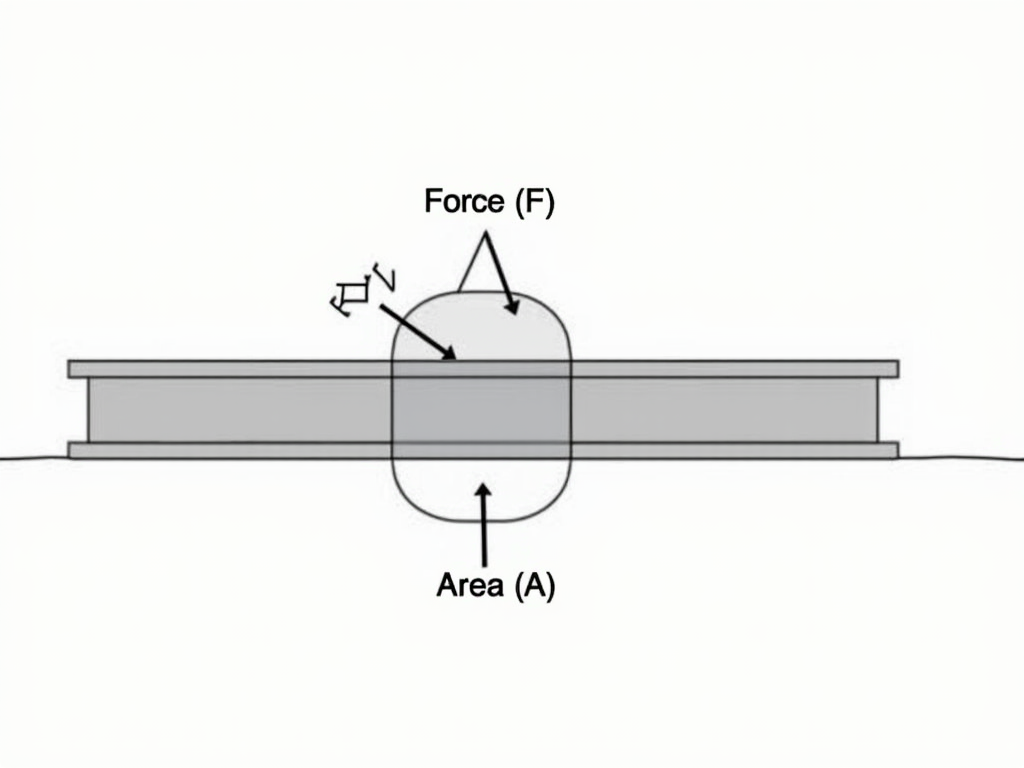

Stress is how much force a material feels over a certain area. We measure it with a simple formula:

Stress (σ) = Force (F) ÷ Area (A)

For example, if you push 1,000 pounds on a 2-square-inch surface, the stress is 500 pounds per square inch.

Strain is how much a material changes shape under that stress. It’s a ratio:

Strain (ε) = Change in Length (ΔL) ÷ Original Length (L)

If a 10-foot rod stretches by 0.01 feet, the strain is 0.001. No units, just a number.

Different Kinds of Stress and Strain

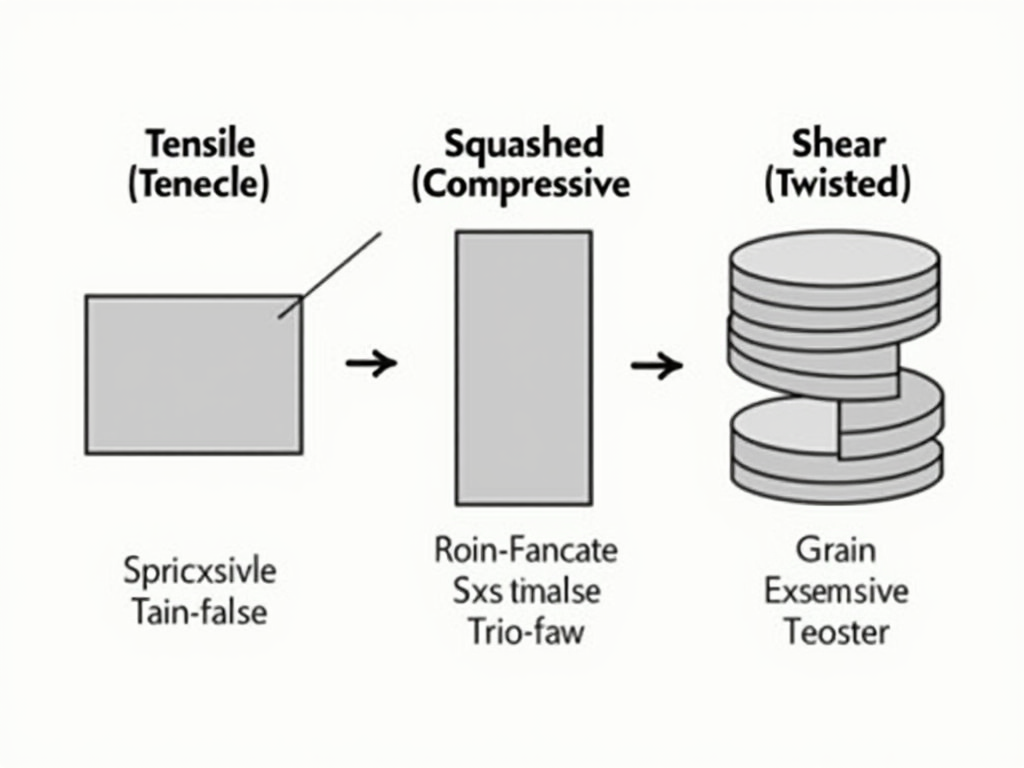

Forces hit materials in different ways. Here’s a breakdown:

- Tensile: Pulling apart, like tugging a rope.

- Compressive: Squeezing together, like stacking books.

- Shear: Sliding or twisting, like scissors cutting.

Materials handle these differently. Concrete takes compression well but struggles with tension. That’s why we add steel to reinforce it. Knowing this helps engineers pick the right stuff for the job.

How We Calculate Stress and Strain

Let’s try an example. Imagine a steel bar with an area of 0.02 square meters. Apply 40,000 Newtons of force. The stress is:

σ = 40,000 N ÷ 0.02 m² = 2,000,000 Pa

Now, if that bar is 3 meters long and stretches by 0.003 meters, the strain is:

ε = 0.003 m ÷ 3 m = 0.001

These numbers tell us if the bar can take the load without breaking.

Load Combinations in Design

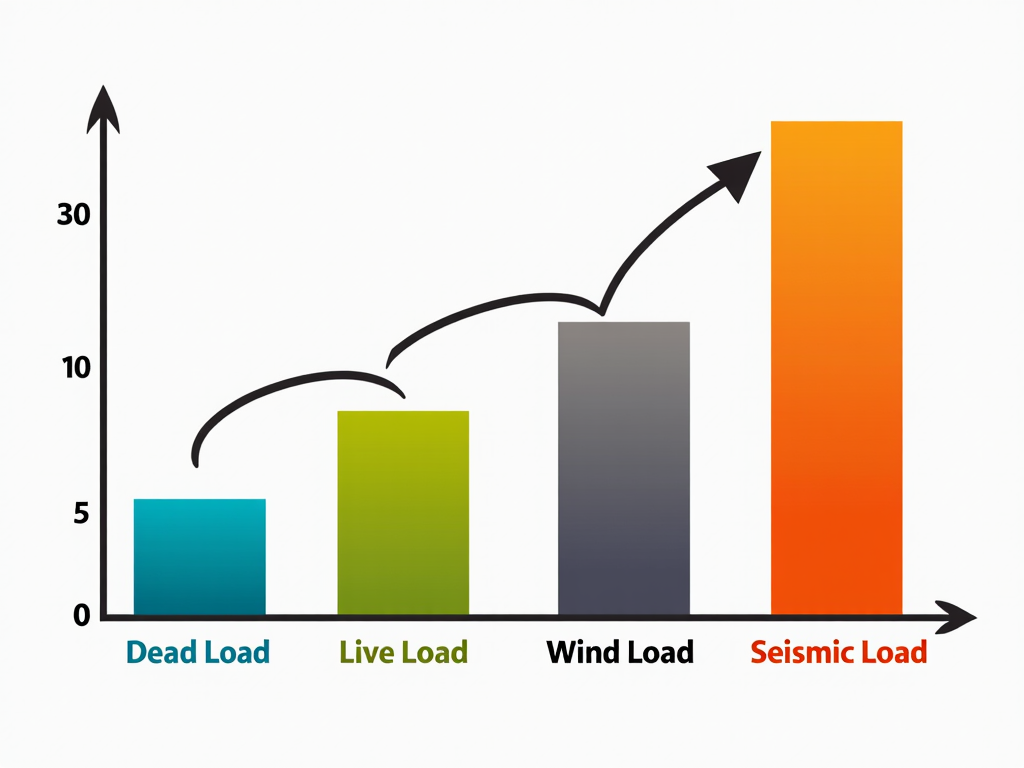

Buildings face all kinds of forces:

- Dead Loads: The building’s own weight.

- Live Loads: People, furniture, anything that moves.

- Wind Loads: Gusts pushing against walls.

- Seismic Loads: Shaking from earthquakes.

Engineers mix these using load combinations. A typical one might be:

1.2 × Dead + 1.6 × Live + 0.5 × Wind

This makes sure the structure can handle everything at once.

Advanced Load Combination Techniques

Sometimes, it gets trickier. In tall buildings or earthquake zones, we use advanced load combination techniques. These might factor in time—like how long wind blows—or direction, like wind hitting from the side. It’s about being extra sure nothing fails.

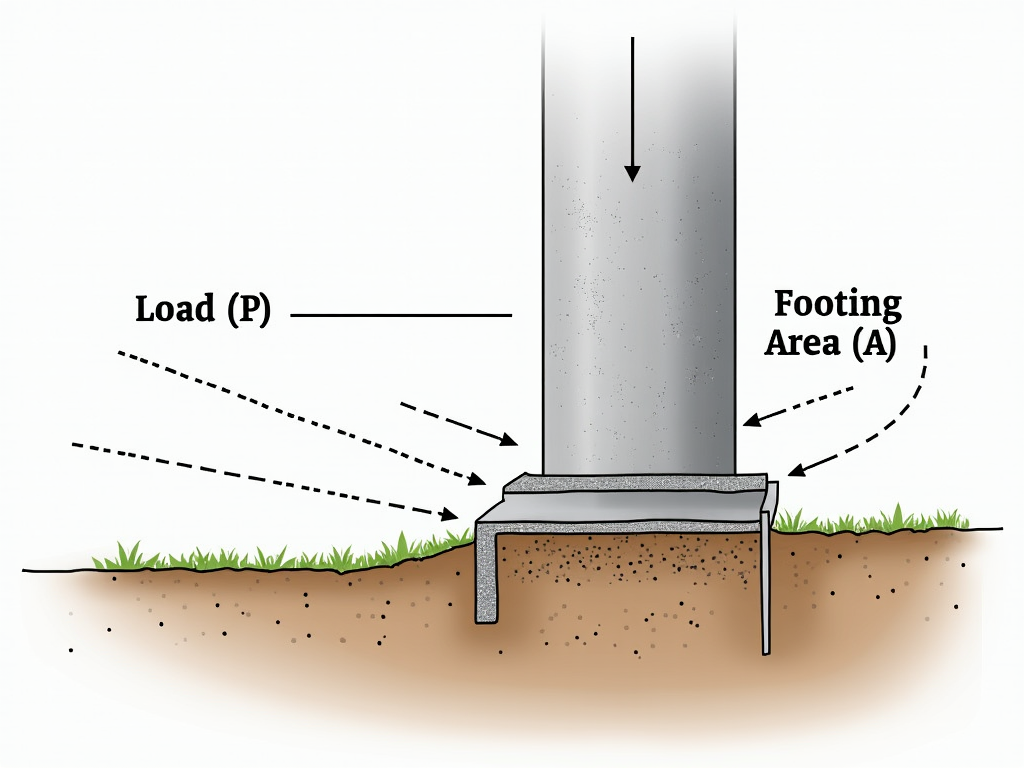

Footing Calculation: Foundations That Work

Footings spread a building’s weight onto the ground. We calculate the stress on the soil like this:

Soil Stress = Total Load (P) ÷ Footing Area (A)

Say a column carries 100,000 pounds, and the footing is 10 square feet. The stress is 10,000 pounds per square foot. If the soil can only take 5,000, we make the footing bigger to spread the load.

Real Projects, Real Stress

Take the Eiffel Tower. Its iron lattice handles wind by spreading stress across many small pieces. Engineers calculated every angle to keep it standing since 1889.

Or consider a bridge I worked on. We found the cables had too much strain under heavy traffic. We thickened them, tested again, and got it right. It’s still holding up today.

My Take on Stress and Strain

I’ve seen these ideas in action. Once, we had a warehouse floor cracking under machine weight. We measured the soil strain, adjusted the footing size, and fixed it. It’s not just math—it’s about solving real problems.

Another time, a client wanted a sleek, thin roof. Stress calculations showed it’d bend too much. We compromised with a stronger material. Balancing safety and design is the fun part.

Why It All Matters

Understanding stress and strain in architectural engineering keeps buildings from falling down. It’s how we make skyscrapers soar and bridges span rivers. Every calculation, every tweak, makes the world safer and stronger.