Basics of Reinforced Concrete Design: A Comprehensive Guide for Civil Engineers

Reinforced concrete shapes the world around us, from towering skyscrapers to sturdy bridges. It’s a brilliant mix of concrete’s ability to handle pressure and steel’s strength under tension. This guide explores the Basics of Reinforced Concrete Design, giving you the know-how to create safe, lasting structures.

What Is Reinforced Concrete?

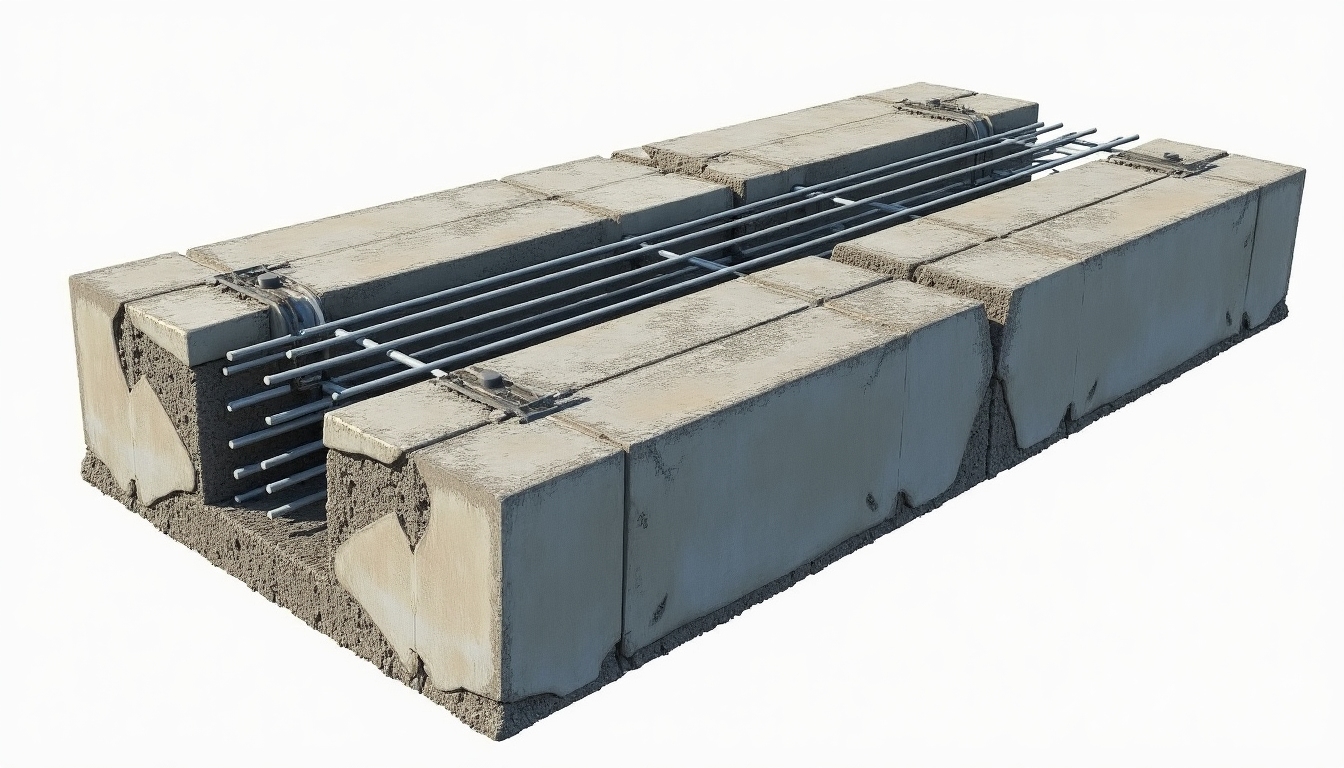

Imagine concrete as a tough guy who can take a heavy punch but flinches at a pull. Steel, meanwhile, is like a flexible gymnast, bending without breaking. Together, they form reinforced concrete—a team that handles all kinds of forces. Concrete resists compression, while steel bars (called rebars) tackle tension. This combo makes buildings, bridges, and dams possible.

Here’s a quick look at their strengths:

| Material | Great At | Weak At |

|---|---|---|

| Concrete | Compression | Tension |

| Steel | Tension | Compression |

This balance is why reinforced concrete is everywhere in construction.

Key Structural Design Principles for Civil Engineers

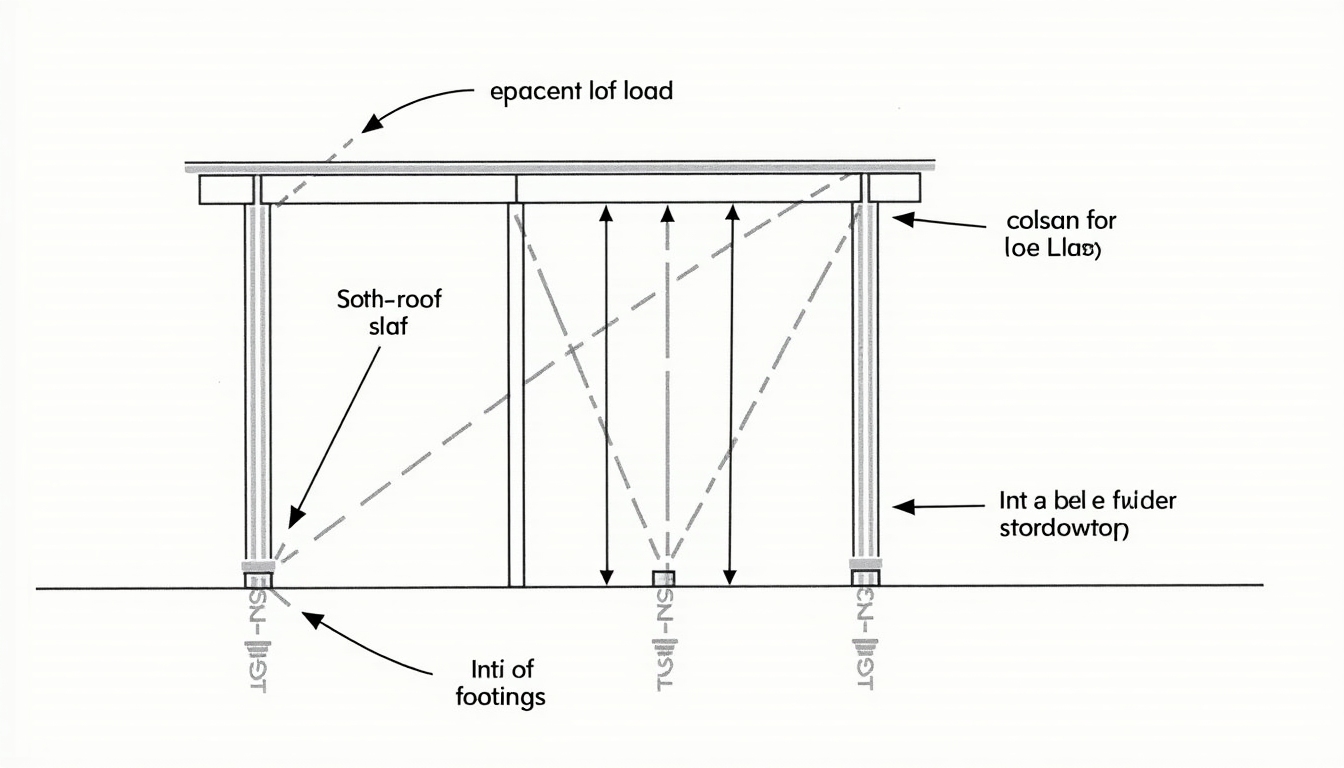

Designing with reinforced concrete means figuring out what a structure must carry. Loads come in flavors: dead loads (the structure’s own weight), live loads (people or furniture), and extras like wind or earthquakes. You calculate these to make sure the building stands strong.

Safety matters most. Codes like the American Concrete Institute (ACI) guide us, adding safety buffers so nothing collapses. I once saw a rookie engineer skip a wind load check—cracks appeared fast. Trust me, precision here saves headaches later.

Slab Design Made Simple

Slabs are the flat parts of a building—like floors or ceilings. They spread loads to beams or columns below. There are one-way slabs (bending in one direction) and two-way slabs (bending both ways), depending on how they’re supported.

Designing a slab starts with its job: how much weight will it hold? Then you pick a thickness to keep it from sagging too much. Next, add steel rebars where the slab bends most. For a one-way slab, I’d place bars along the short direction—say, a 10-foot span with a 6-inch thick slab. A quick calculation ensures it holds up.

Here’s how it’s done: 1. Check the slab’s span and supports. 2. Add up all loads (dead and live). 3. Pick a thickness to limit bending. 4. Calculate steel needed for strength. 5. Lay out bars with enough cover.

Why Slab Design Matters

A poorly designed slab can sag or crack. I worked on a warehouse once where the slab wasn’t thick enough for heavy forklifts—within months, we had to patch it up. Good slab design keeps floors level and safe, no matter the load.

Footing Calculation Basics

Footings sit at the bottom, passing a building’s weight to the ground. They’re like the roots of a tree—without them, everything topples. You’ve got types like isolated footings (under one column) or raft footings (a big slab for the whole base).

To design one, know the load and the soil’s strength. Say a column carries 500 kN (about 112,000 pounds), and the soil can take 150 kN per square meter. Divide 500 by 150, and you need a 3.33 square meter footing. Make it square, and each side’s about 1.83 meters (6 feet). Add steel to handle the pressure underneath.

Steps for a footing: 1. Find the total load from above. 2. Test the soil’s bearing capacity. 3. Size the footing to spread the load. 4. Add steel for extra strength. 5. Pour it right to avoid settling.

Lessons from Footing Design

Get the footing calculation wrong, and the building shifts. I’ve seen a small house tilt because the footing was too small for soggy soil. Check the soil first—every time. It’s a simple step that keeps everything upright.

Best Practices for Success

Details make or break reinforced concrete. Place rebars right—too close, and concrete can’t flow; too far, and strength drops. Cover them with enough concrete to stop rust—I aim for at least 2 inches. Anchor them well so they grip tight.

Mistakes happen. I’ve caught designs missing earthquake loads or skimping on steel. Double-check everything. Use software, sure, but talk it over with a teammate. Fresh eyes spot what you miss.

Real-World Challenges

Construction isn’t perfect. Weather delays concrete pours, or workers misplace bars. Once, a crew poured a slab before I checked the steel—cracks showed up fast. Plan ahead, watch the build, and test the results. It’s how you keep quality high.

Wrapping It Up

The Basics of Reinforced Concrete Design boil down to teamwork—concrete and steel, plus your skills as an engineer. Master loads, slabs, and footings, and you’ll build structures that last. Keep learning, stay sharp, and every project gets better.